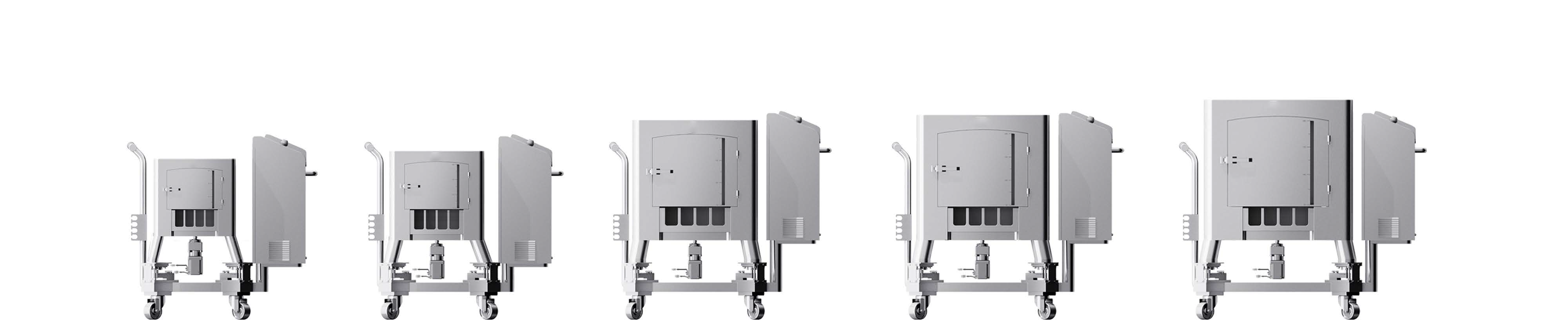

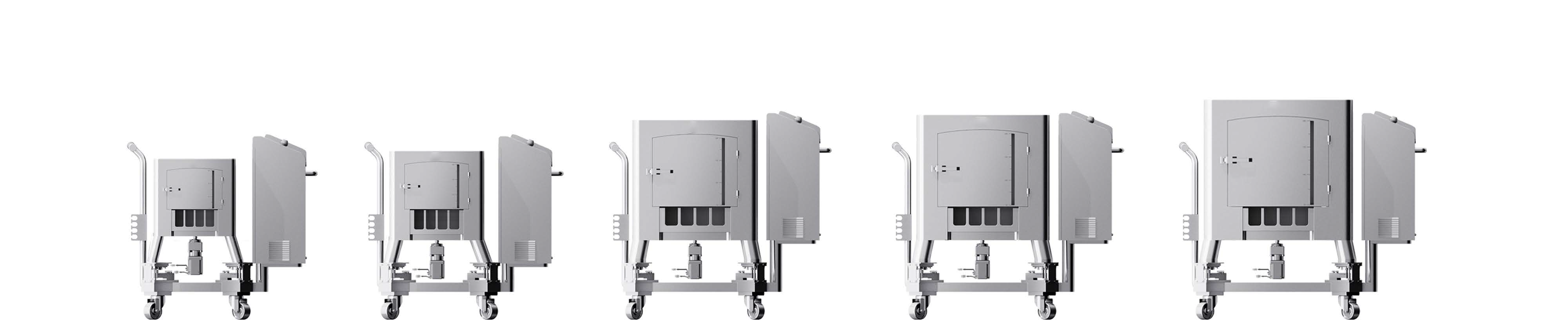

シングルユース撹拌システムマグネットタイプ BIOBGBM

BIOBGBM Single-Use Magnetic Mixing System has a nice and neat appear-ance and is easy to clean, handle and use. The system is specially designed for production mixing in

biotechnology and pharmaceuticals to facilitate lab research, process development, and GMP production.

The system provides an ideal solution for efficient solid/liquid mixing applications. As a flexible mobile mixing platform, the system provides effective and sustainable single-use mixing solutions for different volumes and application types. The system has demonstrated excellent performance in buffer and medi-um preparation.

Applications:

• Medium preparation

• Buffer preparation

• Downstream intermedi-ate product processing

BIOBGBMC Single-Use Integrated Desktop Mixing System

BIOBGBMP Single-Use Integrated Desktop Mixing System

• Bulk purification

• Semi-finished product preparation

Features

• Wide volume range

The single-use mixing system covers various volumes, in-cluding 50 L, 100 L, 200L, 400 L, 500 L, 650 L, 1000 L, 1500 L, 2000L, 2500 L, and 3000 L, so as to meet the requirements of scale-up from R&D to mass production; other volumes can be customized.

• Wide working volume range

The working volume is usually 20%–110% of the mixing sys-tem volume.

• Low residual liquid

With an inclined bottom at an angle of 2–5° ,the liquid out-let is located at the lowest level of the whole equipment, ensuring a low residual liquid ( ≤ 20 mL) and reducing the

loss of feed liquid (dwell volume ≤ 2.5 L for 2500 L and ≤ 3 L for 3000 L).

• Precise mixing

The motor is from Oriental Motor. The rotation speed precision is ±2 rpm. The motor is at a fixed time and fixed speed, can be instantly started and stopped, and no pre-heating or magnetizing is required.

• Polished and wire-drawn

The whole device is made of SS304L with anti-fingerprint polishing (Ra ≤ 0.8 μm),

preventing injuries to soft bags.

• Compact structure

The equipment has a compact plug-and-run structure design and there is no need to

install a driver or controller. The structural design is friendly to users. The shelf and

handle can well protect the weight sensor.

• No condensation

Dimple jackets at four sides enables the temperature of the feed liquid to be

controlled in a short time. Also, insulation layers are provided outside the jackets,

which helps to avoid condensation when the temperature of the feed liquid is lower or

higher than the ambient temperature, meeting the requirements of clean workshops.

• Easy cleaning

No obvious arrangement of wires can be observed on the surface of the equipment.

All wiring is arranged inside the equipment (with waterproof connectors) for a neat

appearance, making it easy to transfer the equipment inside a workshop and clean it

after use.

• Modular design

Various modules are available for different customer demands, including mixing,

weighing, temperature control, pH, cond, peristaltic pump, etc. All core components

and parts are from high-end brands, ensuring the stable control of critical parameters.

• Stable hardware design

The design of window/manual control on the side of the mixing bin facilitates the

installation of bags and allows the visual inspection of the mixing status.

The control interface and mixing bin height are reasonably designed for easier

operation. The rotatable electric-control mixing bin makes it easier to use and clean from multiple angles. The liquid outlet line and safety valve are added to meet the needs of safety and convenience.

• Reliable software control

The standard configuration of the genuine Windows 10 Enterprise Edition, Advantech

IPC, and Siemens PLC en-sures smooth operations. Permission management, audit trail, batch data export, data integrity, and related functions are available, meeting the data

integrity requirements of 21CFR Part 11 and satisfying the requirements for GMP

production. Due to the flexible process formula function newly added, customers can

manually add various standard formulas. Also, the standard formula recording

function coming with the program can save the customer's repeated efforts,

reducing the risk of use.

• Independent control of production

GVS's manufacturing site covers an area of 10,000 m2 and is equipped with

independent sheet metal cutting equipment, bending equipment, polishing

equipment, etc. From raw materials and steel materials to product delivery, the

entire production process is independently controlled by GVS to assure product

quality and control the delivery time.

オプションを選択